bottle vacuum test|vacuum bottle integrity testing procedure : broker Vacuum box check bubble. As a variation on the spray technique mentioned above, in which the escaping gas causes the bubbles, it is possible to place a so-called “vacuum box” with a seal (something like a diver’s goggles) on the . WEBPara a sua viagem com a Azul, você conta com diversos serviços e benefícios que tornam a sua experiência mais completa e confortável. Conheça as nossas opções de check-in, bagagem, assentos, alimentação, entretenimento e muito mais. Aproveite também as melhores ofertas de passagens aéreas para o Brasil e o mundo com a Azul.

{plog:ftitle_list}

Sunderland graduated from West Salem High School, where she excelled academically. She planned to become a counselor or an accountant, but eventually lost interest in doing. Ver mais

Vacuum box check bubble. As a variation on the spray technique mentioned above, in which the escaping gas causes the bubbles, it is possible to place a so-called “vacuum box” with a seal (something like a diver’s goggles) on the .Vacuum leak testing allows for the identification and removal of defective bottles early in the production process. By detecting leaks before packaging and distribution, manufacturers can .

Learn how to test vacuum leaks effectively with our comprehensive guide. Discover the benefits of using the AT2E USA Vacuum Leak Tester Standard Model VLT-ST for accurate and reliable results. Ensure product integrity and .

to test a bottle but not much else. HVI hipots offer far higher current and power ratings, enabling them to test most equipment in a substation. Don’t get caught short with a hipot unable to test . 2 test methods are presented in this video about leak testing for plastic containers in a vacuum chamber. You can identify the source of the problem and find.

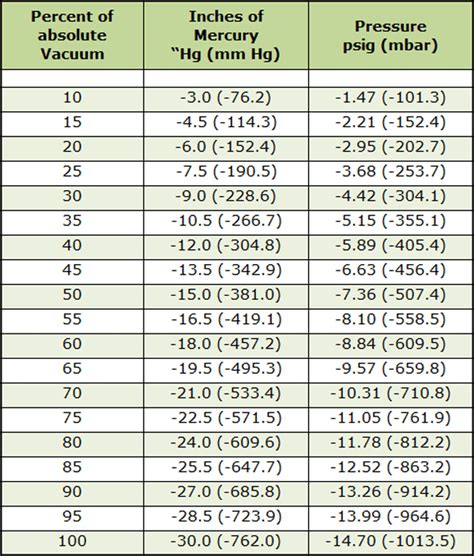

Vacuum bottle integrity testing is a method employed to determine the leak rate of the canned or bottle-type packaging. It is critical to ensure the quality of packaging to prevent contamination .Both are reliable ways of detecting a low-pressure leak. The bubble test is employed up to vacuums of 10 -4 mbar. The pump-down test is conducted by evacuating a closed vacuum .

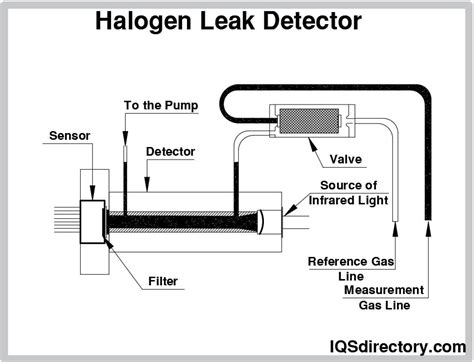

what is a leak detector

For vacuum circuit breakers, this test will also provide an indication of the vacuum bottle integrity. Use manufacturer provided test voltages to avoid potential damage to the bottle. X-Radiation Emissions by Vacuum Interrupters

Learn how to ensure leak-free bottles using a vacuum leak tester. Pacorr's ASTM D6653-compliant vacuum leakage tester guarantees quality and safety in packaging.All Products > Electrical Test Equipment > Vacuum Bottle Testers. Vacuum Bottle Testers. Showing all 4 results. Haefely Hipotronics 7BT60-A 60KV AV Vacuum Bottle Tester. SKU: 7BT60. Megger Vidar – Vacuum Interrupter Tester. SKU: Meg-Vidar. Vanguard VBT-75 Vacuum Bottle Tester. SKU: VBT-75 .

Place the sample (e.g., a bottle, can, or container) in the vacuum chamber. Ensure it is properly positioned and secured. Step 3: Initiate the Vacuum. Start the vacuum pump to reduce the pressure inside the chamber. The VLT-ST .

The VBT-75 S2 is Vanguard's 2nd generation microprocessor-based, portable, 75kV dc vacuum bottle tester designed for testing circuit breaker vacuum bottles in-field & in-shop. MyDoble Login. English. Français; .

vacuum test vs pressure

We see failed bottles every day. contact resistance does not tell you much for vacuum interrupters but it is a standard test. Contact erosion is a much better indicator of condition assessment. No trees were killed in the sending of this message, but a large number of electrons were terribly inconvenienced.

Vacuum bottle integrity testing is a method employed to determine the leak rate of the canned or bottle-type packaging. It is critical to ensure the quality of packaging to prevent contamination and loss. . The vacuum leak test procedure involves the package to place in a chamber that is exposed under vacuum conditions. Pressure transducers . The test object either holds the voltage or fails. There is nothing in-between. DC leakage currents are meaningless. In a bottle, there is no acceptable partial vacuum. It is either there or not. An AC stress test will determine that immediately. Another reason: The DC output voltage from various hipots is not predictable.

For vacuum circuit breakers, this test will also provide an indication of the vacuum bottle integrity. Use manufacturer provided test voltages to avoid potential damage to the bottle. X-Radiation Emissions by Vacuum Interrupters WARNING: X-Rays may be produced Vacuum Water Bottle: : Stainless steel: Triple-wall vacuum: . To test if your bottle still has its vacuum sealing: Carefully fill the bottle with boiling water and wait five minutes. Then .

2 test methods are presented in this video about leak testing for plastic containers in a vacuum chamber. You can identify the source of the problem and find.The vacuum decay leak test is a non-destructive test method used to detect leaks in packaging to ensure container closure integrity (CCI). . Ophthalmic dropper tip bottles containing liquids; Blow Fill Seal bottle or strip containing liquid; Flexible, non-porous packages including bags and pouches containing solids (powders, medical devices) .

Quickly and accurately measure the vacuum inside your corked bottle with our vacuum/pressure gauge.BOTTLE LEAK TEST PROCEDURE 👉🏼 The ASTM D5094* is a LEAK Test Method for Bottles, Caps and Containers.00:00 Intro00:25 Scope00:54 Leak Causes01:32 ASTM D509.Glass or plastic bottles with elastomer closure, containing liquid ; Closed (non-porous) containers containing liquid; Bottles with threaded screw closure, containing liquid; Flexible containers (e.g. IV bags) Vacuum Decay Method: How it works. The Vacuum Decay Method (VDM) uses a vacuum to detect leaks in the product being tested.Product Overview: Vanguard VBT-75 Vacuum Bottle Tester. Vanguard VBT-75 Vacuum Bottle Tester. The VBT-75 is a microprocessor-based, portable, 75kV dc vacuum bottle tester. This lightweight, portable tester is designed for testing circuit-breaker vacuum bottles in the field and at the shop. Test voltages can be selected from 10 kV dc to 75 kV dc .

vacuum leak test standards

Vacuum Bottle Insulation Integrity Test - HighTest Technology - Transformer Test Equipment ~ Circuit Breaker Timer, Winding Resistance, Transformer Ratio Vacuum Interrupter Leak Rate Test Set Up. There will always be some leakage in even the best VIs, and that leakage may be slow enough that the VI will meet or even exceed the manufacturer’s predicted service life. On .

Explore the vital role of vacuum leak testers in quality assurance, covering types, standards like ASTM F 2338-09(2013), and best practices for PET bottles and packaging testing. [email protected] +91-8882149230 Interpretation of DC test results . A vacuum bottle that turns out good in a DC test will also turn out to be good when tested with AC. However, if a bottle appears to be bad in a DC test, the test should always be repeated with the polarity reversed. This is because if there is a microscopic sharp spot on one of the contacts, this may lead to .Buy Stanley Classic Vacuum Insulated Wide Mouth Bottle - BPA-Free 18/8 Stainless Steel Thermos for Cold & Hot Beverages – Keeps Liquid Hot or Cold for Up to 24 Hours: Thermoses - Amazon.com FREE DELIVERY possible on eligible purchases . Boiling Water TEMP TEST Results at 8 Hours and 24 Hours. Robert V. Videos for this product. 0:54 . Click . • The current accepted field service test for vacuum interrupters is a simple Go/No-Go AC Potential Test. • Vacuum interrupters can catastrophically fail at any time taking many days to clean, . vacuum interrupter testing,vacuum bottle testing,vacuum interrupter tester,vacuum bottle testing,vacuum bottle tester Created Date:

The typical design of a Thermos brand vacuum flask, used for maintaining the temperature of fluids such as coffee. A vacuum flask (also known as a Dewar flask, Dewar bottle or thermos) is an insulating storage vessel that slows the speed at which its contents change in temperature. It greatly lengthens the time over which its contents remain hotter or cooler than the flask's .The ASTM D4991 test method provides a standard for leakage testing of empty rigid containers by vacuum. This method ensures container resistance to leakage under differential pressure conditions, such as during air transport. It is suitable for testing rigid containers used for transporting hazardous liquids in accordance with UN TDG and ICAO TIs. This vacuum-insulated bottle uses the brand’s patented TempShield technology, which guarantees cold drinks will remain cool for up to 24 hours while keeping your coffee or tea hot for up to 6. . Have you ever had to hold a bottle upside down to see if it leaks, just to “test” that you closed it properly? Inconvenient as that is, a .• All types of vials, bottles, syringes, blisters, pouches, bags, etc. • Small volume generally (< few liters) . Test (External Vacuum): ASTM D3078 • Submerge test sample in water or other suitable fluid in vacuum chamber • Evacuate chamber to target pressure; hold for pre- determined

Adhesive Tape Tester solution

Sanatron Makes The Only Vacuum Bubble Leak Test Chamber Robustly Designed And Quality Manufactured To Consistently Perform And Meet Your Needs! USER MANUAL: [Document #:808873] - PDF. . These can be bags, pouches, bottles, cans, or anything else that has air inside and will emit bubbles if there is a leak and a pressure difference.The pressurized test specimen is submerged in a liquid bath. Rising gas bubbles indicate the leak. Leak detection will depend greatly on the attentiveness of the person conducting the test and involves the temptation to increase the “sensitivity” by using ever higher temperatures, wherein the applicable safety regulations are sometimes disregarded.

60kVAC, 10 mA, Vacuum Bottle Test Set (120V) with Bluetooth; 2-piece design; Center-tapped high voltage transformer; High voltage On/Off pushbuttons with indicator; Automated or Manual control of output voltage; Remote control via Bluetooth connection (Android tablet and software included) Test report generation and test data storage

Initial Adhesion Tester solution

WEBMassagem Á Domicilio. Gravataí (Rio Grande do Sul) 94010-000 Centro. E-mail verificado Luiz massagista . - Gravataí Atendimento das 08:00 ás 18:30 de segunda a sábado. .

bottle vacuum test|vacuum bottle integrity testing procedure